Thousands of chemicals and biological pollutants are found indoors, many of which are known to have significant health impacts. The EPA estimates we spend up to 90% of our time indoors. Solutions currently available fail to effectively address the full spectrum of indoor air quality concerns. With these facts, improving our indoor air quality is a top priority. The Promethium system provides an easy, safe, and effective way to do just that – at scale.

Promethium’s proprietary photocatalytic solution, GreenBlend, represents a paradigm shift in air quality technology.

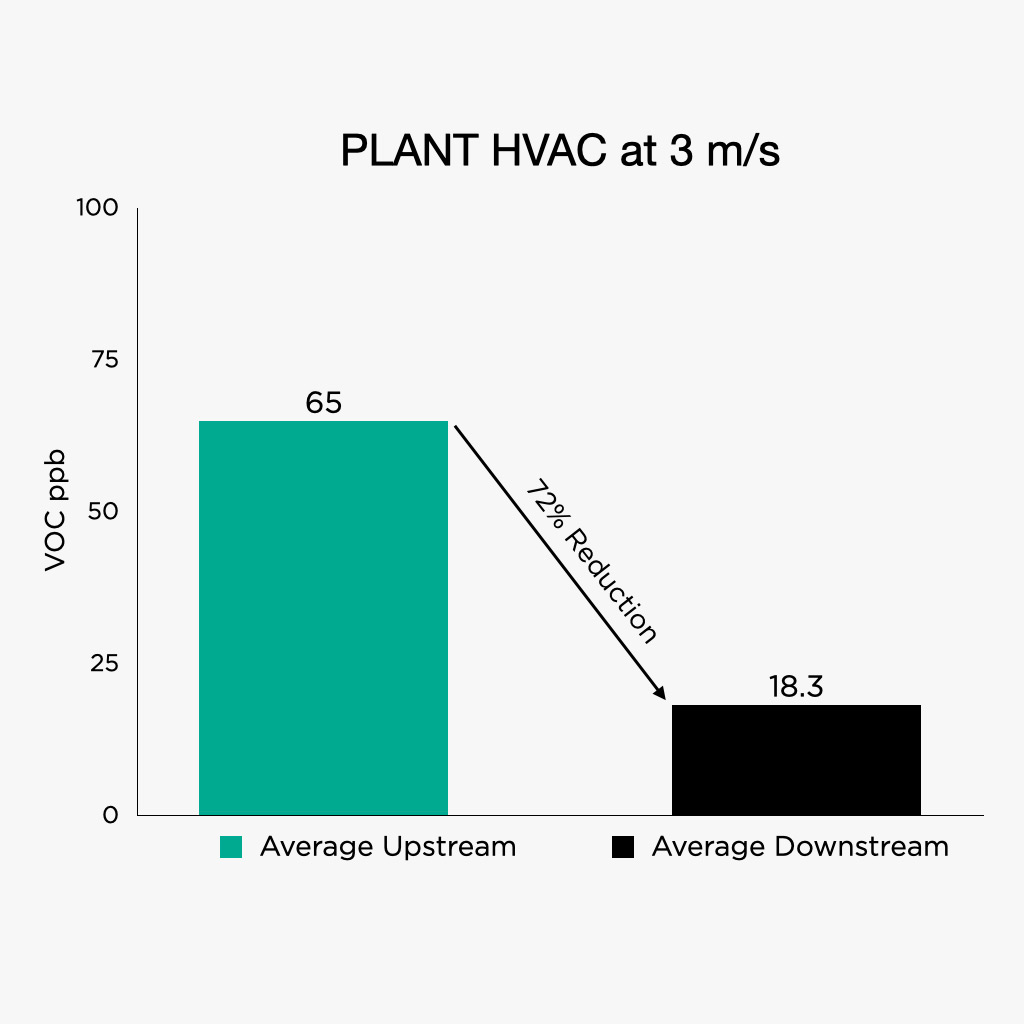

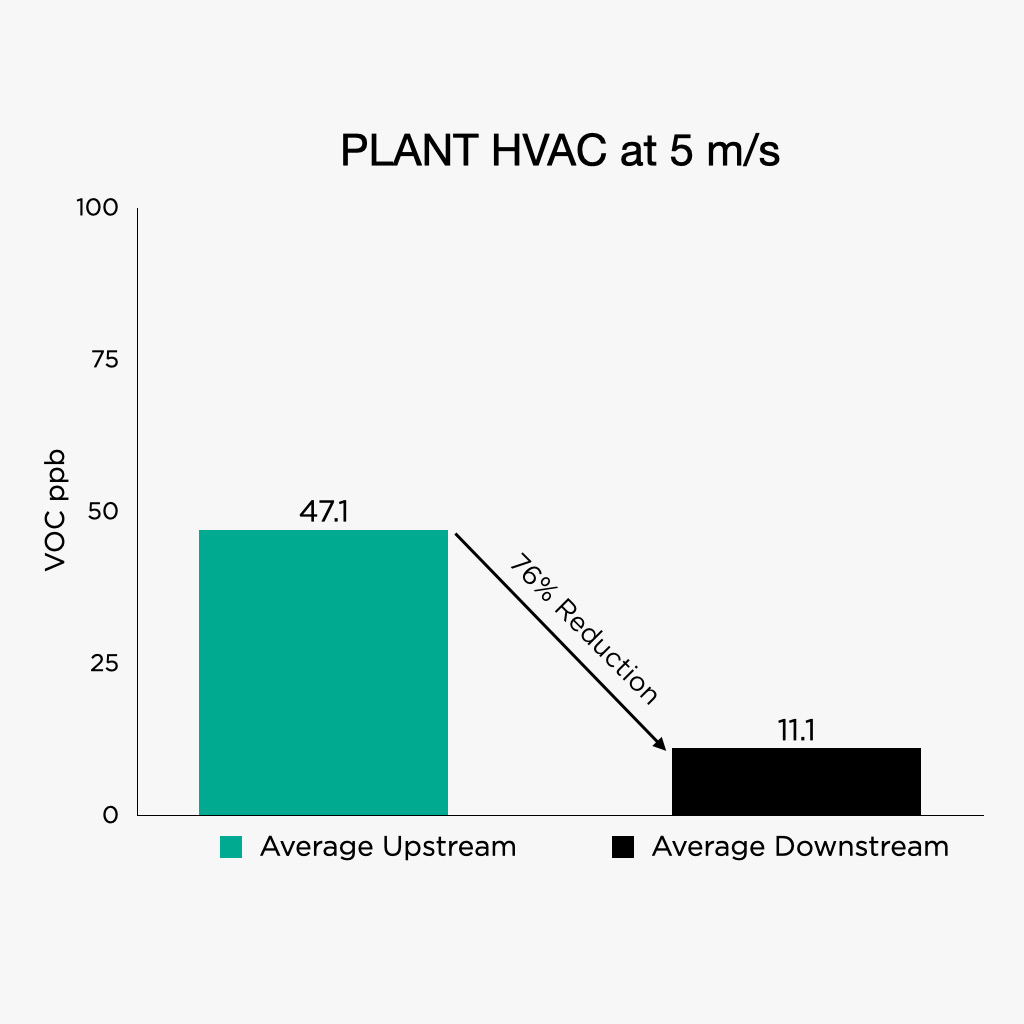

Promethium’s flagship PLANT HAVC system can deliver clean air at a rate of 5,000 CFM with a 0.125” w.c. pressure drop and 285 W of power.

What is CFM?

Cubic Feet per Minute (CFM) is a measure of how quickly air can move through a space. Volumetric flow rate (VFR) formulas are used to convert larger units of mass (pounds, tons, etc.) into units of volumetric flow. The volume of air is usually determined by measuring the cross-sectional area (A), the length (L), and the height of the space (H): VFR = A x L x H. This metric is key in determining the effectiveness of an air purification system.

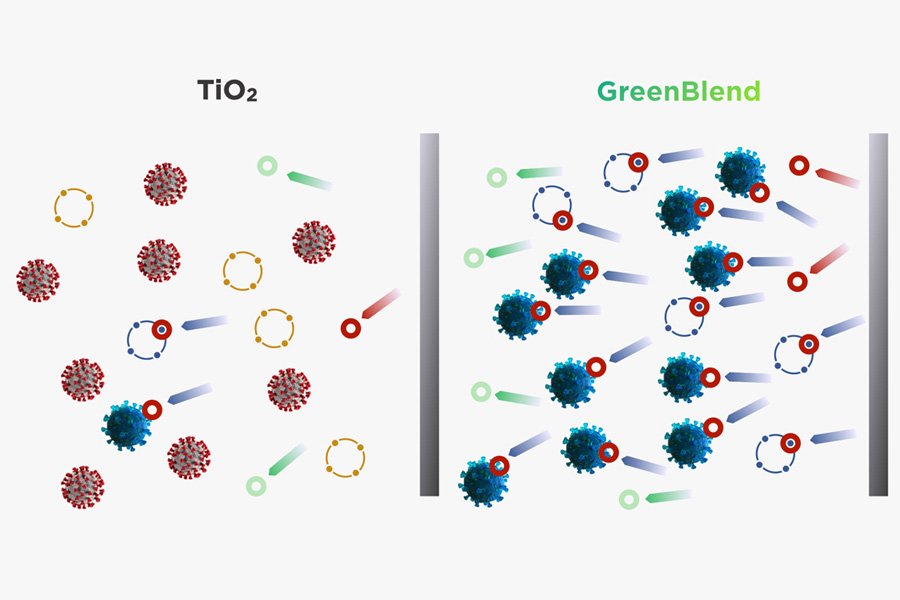

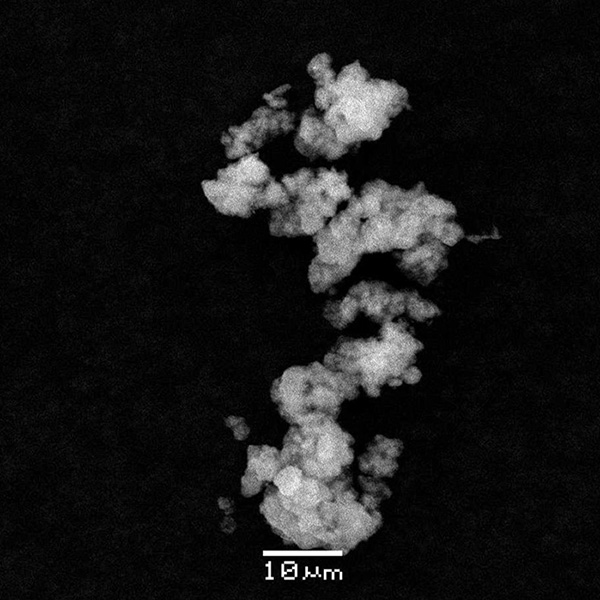

Figure 1 – TiO2 Nanoparticles

Photocatalytic oxidation (PCO), initially discovered in Japan in 1972, has since been adopted for applications ranging from space exploration to sustainable water treatment. A photocatalytic air purifier is composed of an ultraviolet lamp, a photocatalytic media, and channels for directing air. The catalyst is typically in the form of a titanium dioxide (TiO2) coating, or small beads arranged in specific patterns. The lamp generates light in the ultraviolet range, which is invisible to the human eye, but which initiates the chemical reactions that break down contaminants in the air. As air is directed through the channels, the catalyst-coated surfaces of the media break down the organic molecules and gases in the air. These by-products are generally harmless and dissipate into the air. Some of the organic molecules are converted into water vapor.

Although there are many brands of photocatalytic air purifiers, most are based on the same general technology. While TiO2 was the first photocatalyst on the market, it is far from optimized. This often led to incomplete mineralization and thus the formation of undesirable byproducts.

At Promethium, we pride ourselves on being pioneers in PCO technology. Promethium’s PCO technology has been independently tested and proven to significantly reduce airborne bacteria, viruses, gasses, and VOCs (volatile organic compounds). Our systems are designed and manufactured by leading American engineers and are built to stand the test of time, backed by a lifetime guarantee. They have the lowest maintenance requirements in the industry and are guaranteed to produce clean air for years to come. Key features of our PLANT systems include:

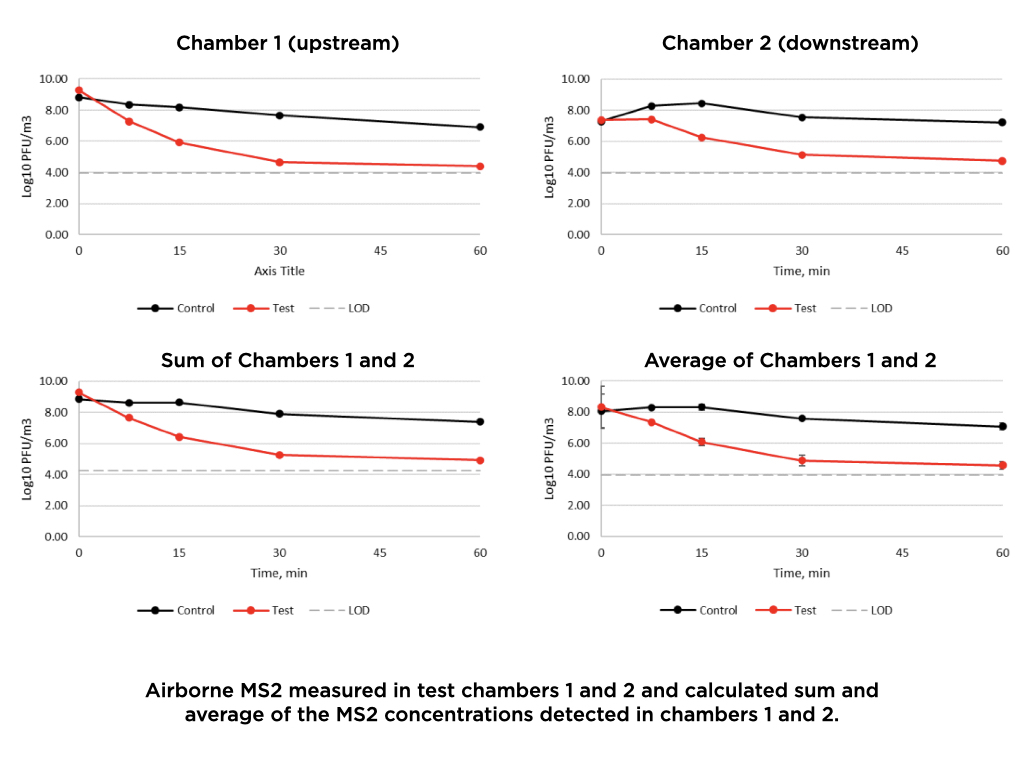

- Removes 99% of pathogens in 20 minutes [1]

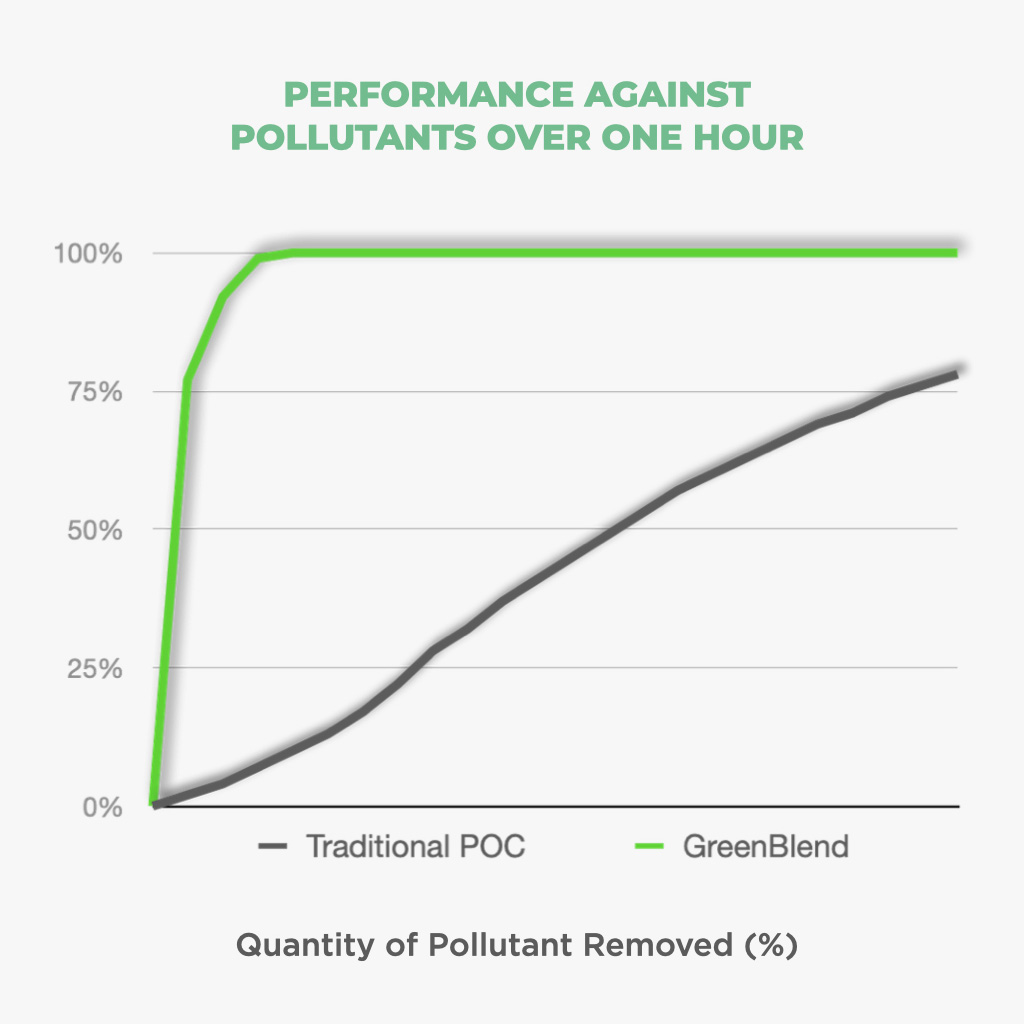

- Removes 99.7% of VOCs in 1 hour [2]

- 5,000+ CFM Capacity

- VOC, gas, particulate, mold, and aerosol removal

- 80x the PCO performance compared to TiO2

- Industry-leading activation spectrum

- Ozone-free

- Cyclic durability

[1] – Airmid Laboratories.

[2] – Herrick Laboratories & Warsinger Water Lab.

Promethium’s industry-leading activation spectrum enables the PLANT systems to utilize both visible and UVGI wavelengths of light. The PLANT systems shift the paradigm of what is possible in air quality management and sets the standards for the needs of today and tomorrow.

What is UVGI?

In hospitals and food processing plants, Ultraviolet Germicidal Irradiation (UVGI) light is used to kill airborne pathogens that can cause infection to patients, and cross contamination, respectively. UVGI light penetrates the cell walls of microorganisms, disrupting their DNA and ultimately destroying the organism. UVGI light at a proven wavelength of 254 nanometers is used for germicidal applications since other wavelengths are prone to ozone production.

Promethium’s PLANT systems combine state-of-the-art material science with tried and tested technologies, all managed by the latest sensing and connectivity equipment. Combined with highly reflective aircraft-grade aluminum and high-output UVGI bulbs, Promethium’s PLANT series maximizes dwell time for both sanitation and PCO activation at volumetric flow rates of 5,000 CFM or greater, and a pressure drop of 0.125” w.c. Additionally, the unit responds to the needs of the space, automatically shutting off when not in use. The PLANT ecosystem of devices maintains robust connectivity, offering real-time air quality monitoring, and service status notification.

What is dwell time?

Dwell time has two distinct definitions:

1) The actual time UVC bulbs are exposed to the airstream (e.g. 1 minute)

2) The amount of time it takes for a contaminant to pass through a system (e.g. 1 minute plus the time it takes the contaminant to travel a certain distance)

Both definitions are important to ensure the system is working properly. The dwell time for the UV system is built into the design of the equipment. The amount of dwell time dictates the flow rate, as dwell time must be balanced with the UVC dose – the amount of UV energy delivered (measured in mJ/cm2) per unit time.

Inspired by nature in both function and form, Promethium’s approach miniaturizes and supercharges the natural cleansing processes occurring in the upper atmosphere, without an imposing footprint. Our PCO elements are:

- Designed and built to exacting standards, ensuring greater reliability, higher air flow and longer life than traditional PCO elements.

- Built with no moving parts, reducing the need for maintenance.

- Coated with a catalyst that is resistant to thermal and environmental degradation.

- Ideal for hospital environments, where infection, mold and odor are primary concerns.

- Used in office buildings, athletic facilities, hallways, restrooms, and anywhere harmful contaminants may be present.

At Promethium, we pride ourselves on being pioneers in PCO technology. Promethium’s PCO technology has been independently tested and proven to significantly reduce airborne bacteria, viruses, gasses, and VOCs (volatile organic compounds).

Our systems are designed and manufactured by leading American engineers and are built to stand the test of time. Our units are backed by a lifetime guarantee. Our systems have the lowest maintenance requirements in the industry and are guaranteed to produce clean air for years to come.

Key features of our PLANT systems include:

- Removes 99% of pathogens in 20 minutes [1]

- Removes 99.7% of VOCs in 1 hour [2]

- 5,000+ CFM Capacity

- VOC, gas, particulate, mold, and aerosol removal

- 80x the PCO performance compared to TiO2

- Industry-leading activation spectrum

- Ozone-free

- Cyclic durability

Promethium’s PLANT systems combine state-of-the-art material science with tried and tested technologies, all managed by the latest sensing and connectivity equipment. Combined with highly reflective aircraft-grade aluminum and high-output UVGI bulbs, Promethium’s PLANT series maximizes dwell time for both sanitation and PCO activation at volumetric flow rates of 5,000 CFM or greater, and a pressure drop of 0.125” w.c.

Additionally, the unit responds to the needs of the space, automatically shutting off when not in use. The PLANT ecosystem of devices maintains robust connectivity, offering real-time air quality monitoring, and service status notification.

What is dwell time?

Dwell time has two distinct definitions:

1) The actual time UVC bulbs are exposed to the airstream (e.g. 1 minute)

2) The amount of time it takes for a contaminant to pass through a system (e.g. 1 minute plus the time it takes the contaminant to travel across a certain distance)

Both definitions are important to ensure the system is working properly. The dwell time for the UV system is built into the design of the equipment. The amount of dwell time dictates the flow rate, as dwell time must be balanced with the UVC dose – the amount of UV energy delivered (measured in mJ/cm2) per unit time.

Photocatalytic oxidation (PCO), initially discovered in Japan in 1972, has since been adopted for applications ranging from space exploration to sustainable water treatment. A photocatalytic air purifier is composed of an ultraviolet lamp, a photocatalytic media, and channels for directing air.

The catalyst is typically in the form of a titanium dioxide (TiO2) coating, or small beads arranged in specific patterns. The lamp generates light in the ultraviolet range, which is invisible to the human eye, but which initiates the chemical reactions that break down contaminants in the air.

As air is directed through the channels, the catalyst-coated surfaces of the media break down the organic molecules and gases in the air. These by-products are generally harmless and dissipate into the air. Some of the organic molecules are converted into water vapor.

Although there are many brands of photocatalytic air purifiers, most are based on the same general technology. While TiO2 was the first photocatalyst on the market, it is far from optimized. This often led to incomplete mineralization and thus the formation of undesirable byproducts.